Tending Systems enable full machine utilization

Why is robotic machine tending a smart investment for automated manufacturing?

It operates more quickly than humans because it handles time-consuming, repetitive, and error-prone tasks. Additionally, it reduces labor costs.

|

+x

Robots carry out tasks with precision, do not experience fatigue, and are free from the repetitive strain injuries that often accompany manual picking jobs.

|

+y

Each robotic tending application uses comprehensive design and programming practices to assist manufactures in increasing capacity, cutting scrap, and realizing their just-in-time production goals.

-

Multi-Part Handling

-

Feeding Equipment

-

Laser Marking

-

Multi-Robot Shared Workspace

-

Peripheral Equipment Interfacing

Swaging and Forming Machines

Standard Case Packing, Palletizing and full end of line solutions

Blue Onyx Systems robotic systems are perfect for automating tasks in and around injection molding processes. Gain a competitive advantage by keeping each cell compact, safe, and flexible.

-

Sprue Removal

-

Vision Inspection

-

Overhead & Gantry Mounting

-

Tool Changing

-

Rack Out

Injection Molding

Automation equipment and Robotic Systems

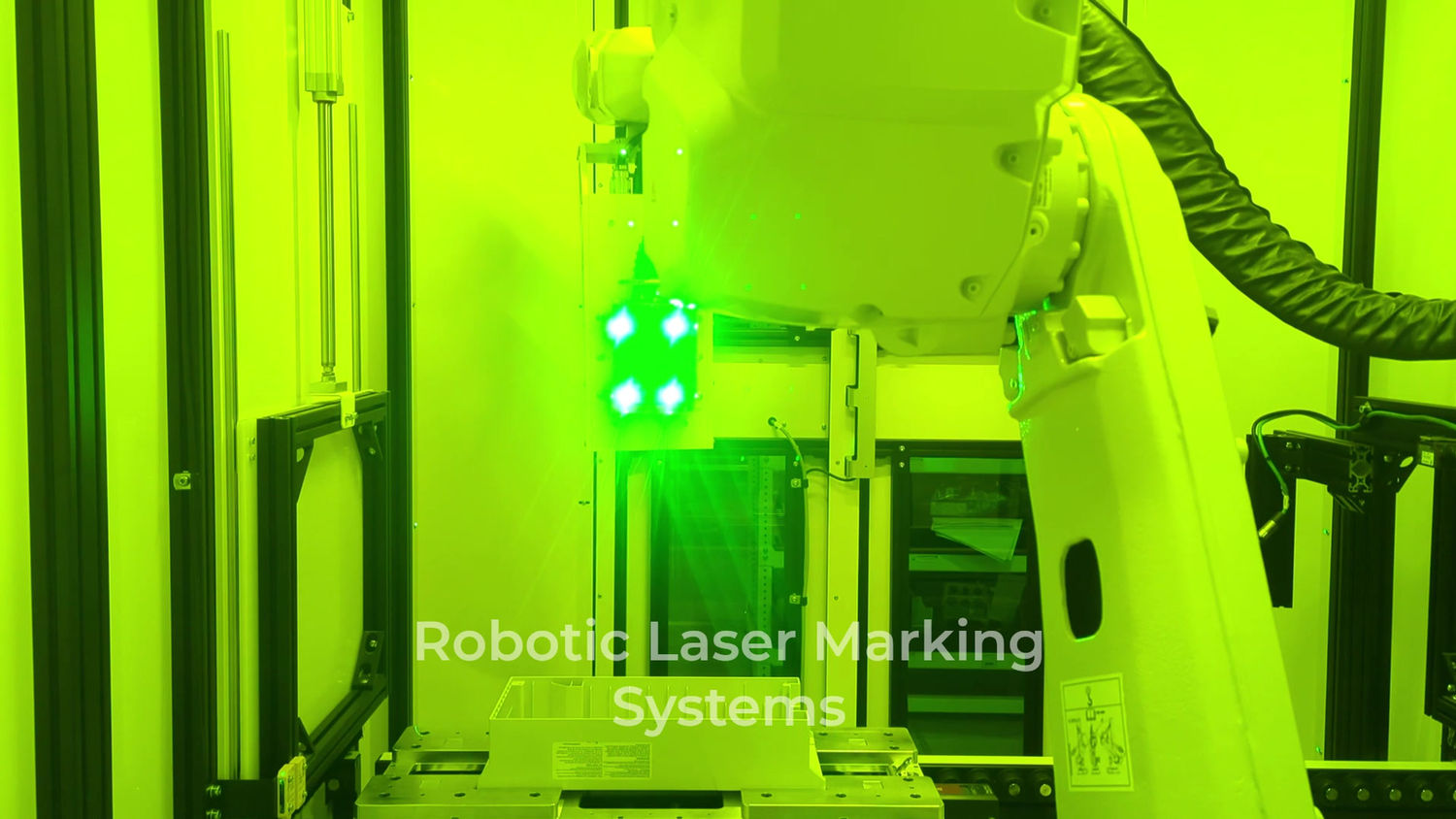

Elevate your precision and speed up the process using robotic part handling for laser machinery. Laser systems can also be mounted to 6-axis robots for added flexibility and control.

-

2D Fiber Lasers

-

CO2 Lasers

-

Marking

-

Laser Cutting

Laser Marking Systems

Machine vision systems, robotics guidance, automated ID, and a full line of inspection systems

Don't let part handling difficulties hold back your machine performance. Blue Onyx Systems robotic solutions are equipped to communicate seamlessly with machining centers to optimize safety and performance.

-

Multi-Part Handling

-

Tool Changing

-

Peripheral Equipment

Machining Centers

Standard Case Packing, Palletizing and full end of line solutions

Automated packaging equipment reduces production time and lowers unit costs. Blue Onyx Systems multiplies the equipment benefits further by robotically feeding raw materials and/or post processing the packaged product.

-

Bagging Machines

-

Filler Machines

-

Form, Fill, Seal Machines

-

Premade Pouch Machines

Packaging Machines

Automation equipment and Robotic Systems

By utilizing the latest in robotic technology, Blue Onyx Systems designs press brake work cells that provide the best returns on short run and high-volume production. For more information, visit our dedicated press brake page.

-

Electric Press Brakes

-

Hydraulic Press Brakes

-

Shears

-

Custom Punch Tables

-

Custom Gantry Feeders

-

Racking / Pack Out

Press Brake System

Machine vision systems, robotics guidance, automated ID, and a full line of inspection systems

Robotic Machine Tending Systems keep your Production Running

Explore our range of cutting-edge robotic machine tending systems designed to optimize your production processes. Our engineering team is dedicated to providing top-notch service, support, and maintenance contracts tailored to your needs.

A Robotic Automation System can enhance your bottom line.

ROI - 18 months

Recover your investment quickly due to reduced downtime, higher throughput, and lower labor costs

Labor savings 20-40%

Robotic systems can offset labor shortages and reduce dependency on hard-to-fill operator roles

Injury risks reduced 25%

Automating repetitive or hazardous loading tasks reduces strain injuries and improves workplace safety

Channel: Robotic Handling Systems